Heat Transfer Technology

Industrial solutions

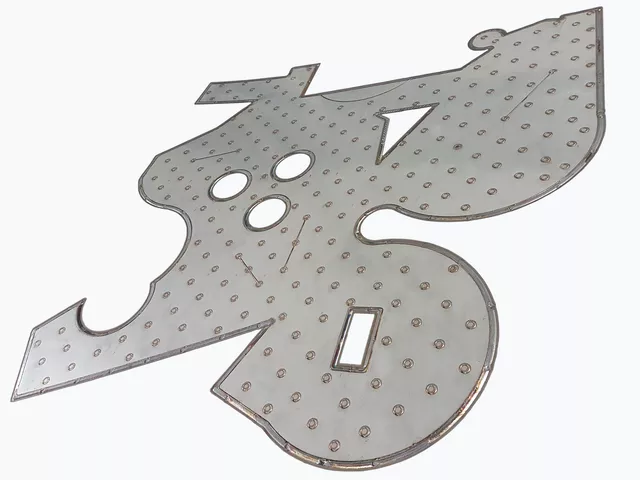

Dimple plates are integral components used in many engineering projects due to their success in optimizing heat transfer efficiency in the field of fluid mechanics with their flexibility, cost-effectiveness, and more. We will dive engineers what a dimple plate is and why it has such an indispensable role within modern engineering design in order to to gain superior confidence when navigating the complex topic of dimple plates.

Since the foundation of Heat Transfer Technology AG, priority has been given to the thermal calculation of industrial heat exchangers. Correspondingly we profit out of our Know-how in fluid mechanics of dimple plates. Furthermore it is enforced by decades of practical experience in this field. As a result of optimized heat transfer and pressure loss calculation. Constructively as well as by manufacturing technology with dimples plate made of stainless steel or mild steel.

Our Products

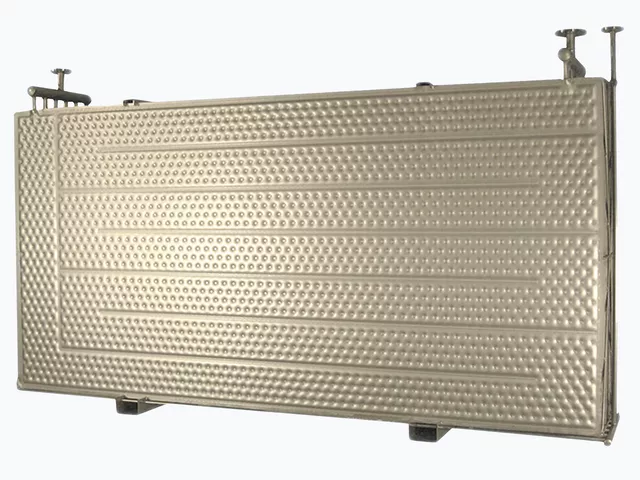

We primarily focus on thermo process technology and the calculation of heat exchangers as heat transfer plates. This is achieved through optimized calculations for heat transfer and pressure drop. Subsequently, this is implemented in terms of construction and manufacturing by using stainless steel or mild steel heat transfer plates, depending on the application and heat transfer requirements. To compare various heat exchangers and make informed decisions, it is important to consider the advantages and disadvantages of each product and perform a cost-benefit analysis. An essential factor in this regard is operational safety and stability, allowing the company to save energy and use heat exchanger products more economically.

Solutions

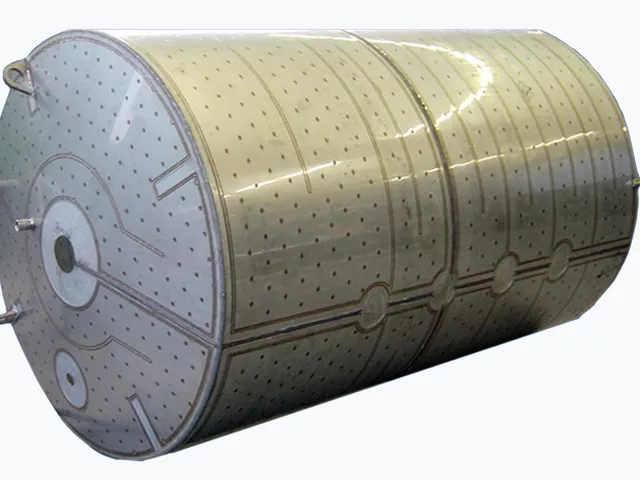

The main focus is on integrating the heat exchange plate or heat exchange system made of stainless steel or mild steel into complex process plants of various applications. Our products and services meet the highest quality standards. Additionally, they are individually tailored to meet the spatial, hygienic, and process requirements of our customers.

Examples Of Our Daily Heat Transfer Tasks

- Do you have notable load peaks to cool at changing flows and temperatures?

- Do you want to minimize the refrigerant volume of your unit in operation?

- Do you want to exploit your polluted exhaust gases or steam for heat recovery?

- Do you want to cool fluids with corrosive or bioactive components? ( e. g. seawater)

- Do you want to move a liquid in an agitator vessel and temper it at the same time?

- Do you have high standards for hygiene and need access at any time without long disassembly, without gaskets to replace?

- Do you want to cool food or beverages down to near the freezing point?

- Do you have to guarantee safety of operation of your cooling device, even during maintenance?

- Do you want to increase your cooling capacity by using your old, existing refrigeration plant?

- Do you want to release your electricity grid from electricity peaks produced by a refrigeration unit?

- Do you know drum ice makers, but want to cut ice production costs to half the amount?

- Do you want to cool fish or meat down to near the freezing point?

- Do you need a huge cooling capacity, but have limited floor space available?