Heat Transfer Technology AG

Industrial heat transfer technology solutions with competence in heat transfer and fluid mechanics

Since the foundation of Heat Transfer Technology AG, priority has been given to the thermal calculation of industrial heat exchangers. Correspondingly we profit out of our Know-how in fluid mechanics of dimple plates. Furthermore it is enforced by decades of practical experience in this field. As a result of optimized heat transfer and pressure loss calculation. Constructively as well as by manufacturing technology with dimples plate made of stainless steel or mild steel.

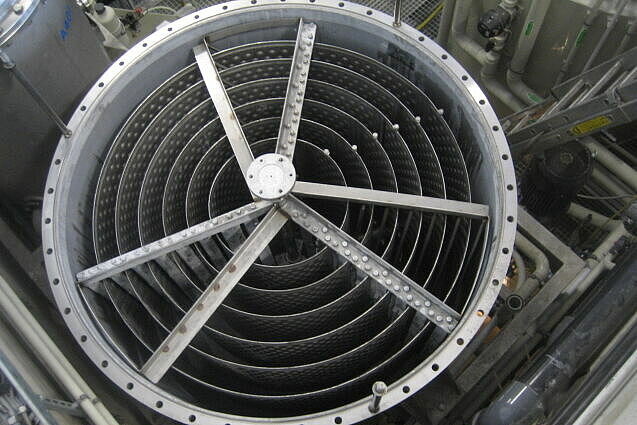

Pillow Plate Heat Exchangers consist of a bundle of pillow plates characterized by their wavy "pillow-shaped" surface and fully welded construction. They offer a promising alternative to conventional shell-and-tube apparatus for the process industry. The complex geometry of the pillow plate channels is created using deformation simulations based on the Finite Element Analysis (FEA). This method allows for an accurate replication of the real wavy surface of the pillow plates. We have conducted extensive CFD studies on the fluid dynamics and heat transfer in the inner and outer channels of the pillow plate heat exchangers to achieve process stability and performance reliability for our customers. We use the validated numerical results to provide design equations for the pressure drop coefficient and Nusselt number for forced turbulent flow in pillow plate heat exchangers for calculations in our projects.

Heat transfer dimple plate specialist

The high qualification, motivation and many years of experience of our employees guarantee solutions of the highest standard. This meets the highest degree of complexity. We supply technical systems and components to meet the specific needs and expectations of our refrigeration and dimple plate heat transfer customers. As a result, they are strictly tailored to functionality, efficiency and value retention in the respective field of application. Cost and efficiency of heat exchangers are in the foreground. Through the ongoing integration of the latest production technologies and the continuous expansion of the engineering and manufacturing experience of dimple plates, we are able to meet the increasing customer requirements.

Process technology and know-how

Heat Transfer Technology AG provides the know-how of process technology. This cooperation is a successful combination for the customer as such. Heat Transfer Technology AG employs mechanical process engineers to give assistance for the customer’s process technology. In the foreground is the integration of the dimple plate or the dimple plate heat exchanger system into process engineering plants of various applications. Dimple plate products and services meet the highest quality standards. In addition, they are individually tailored to the spatial, hygienic and procedural requirements of our customers.

Cooperative Partnerships

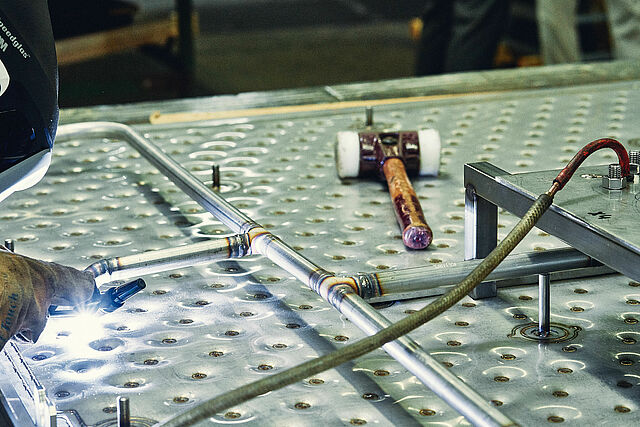

Heat Transfer Technology AG works in close technical exchange with the company BUCO Wärmeaustauscher International GmbH form Geesthacht, Germany for the design and thermal calculation, as well as with the company BUCO laserplate GmbH from Geesthacht, Germany for the production of pillow plates. The company BUCO has been working for more than 100 years with process engineering, thermodynamics and welding technology. Accordingly, the focus in process engineering is on the heat transfer and the calculation of heat exchangers. The focal point of production is the laser welding technology from the market leader Trumpf GmbH + Co. KG, which is decisive for us in our laser welding quality. It guarantees the highest laser welding quality of plate coils in all manufactured products. BUCO refers on their long-standing knowledge and experience.