Product cooling using chip ice heat transfer

Product cooling, for example, fish cooling with chip ice at -0.5°C near freezing point

In order to preserve high-quality fish raw materials, it is crucial to improve knowledge about the utilisation of the cold chain. The cold chain is currently one of the most effective methods of preservation to ensure the quality of hydrobiological products over long storage periods. All fish preservation methods aim to inactivate tissue enzyme activity and destroy living microorganisms. Cooling extends the shelf life of the raw material without significantly impairing its properties and quality. In this way, high-quality fish raw materials can remain fresh and unchanged over a long period of time.

This is particularly important for the trade and marketing of fish products in order to ensure a high level of customer satisfaction. Effective cooling can help to reduce the spoilage of fish products and thus improve the profitability of the industry. In addition, good cooling methods can also help to minimise health risks for consumers, as low temperatures inhibit the growth of potentially harmful bacteria and therefore ensure product safety.

Energy consumption advantage of a BUCO Industrial Ice machine in direct product cooling

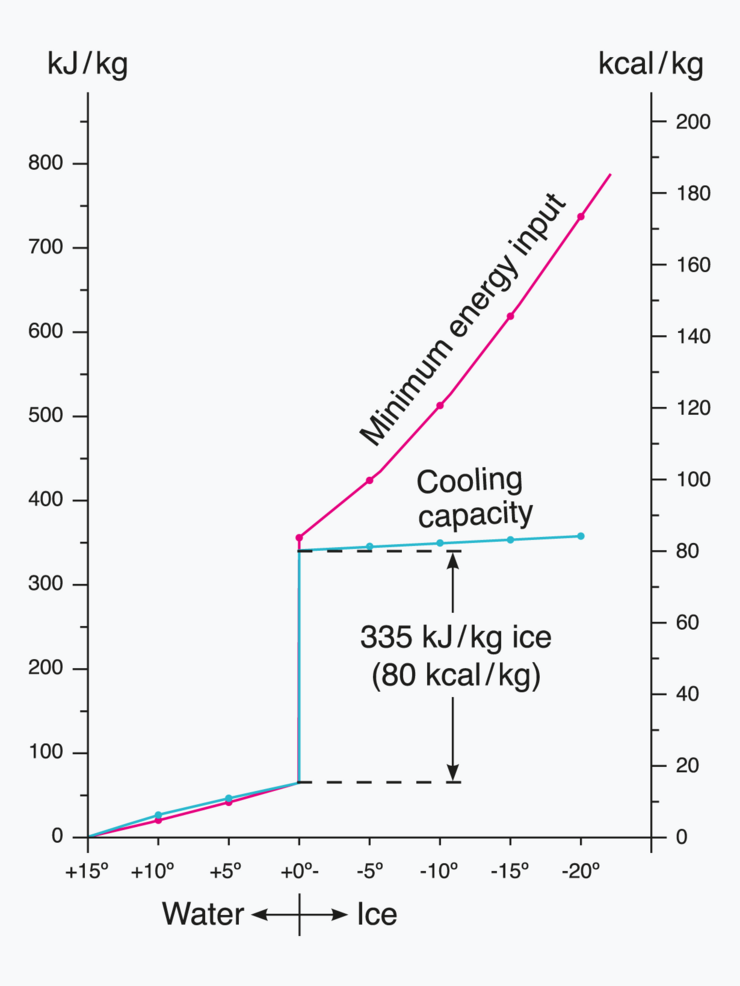

To produce ice, we do have the efficiency in prior focus. Only by melting of the ice, the heat for cooling of the water is taken from the surrounding. Ice is melting at a temperature of 0°C to water and gives 335 kj per kg ice. Therefor we do produce ice with an evaporation temperature T0= -10°C, which generates ice at a temperatures of T= -0.5°C to -1.0°C. The idea is simple, as the cooling gain for subcooling of the Flake Ice in conventional drum systems is down to T= –8°C, which is only approx. 8% of a higher melting capacity. Unfortunately this has a high energy consumption impact for the drum ice machines as such:

Energy cost comparison of a BUCO Industrial Ice machine and a conventional drum system as main cost factor for direct product chilling

Example: 30 to ice / day

Necessary refrigeration power including losses: ca. 150 kWref

Electric power for the drive of the refrigeration machine:

-30 / 35 °C with COP = 1,8 Pel = 84 kWel – Drum system – Flake Ice

-10 / 35 °C with COP = 3,6Pel = 42 kWel – BUCO Ice Pack

Additional drives: 6 kW

Price for electricity: 0,15 € /k Whel

Running costs at -30 °C : 324 € / day or 11 € / to ice – Drum system

Running costs at -10 °C : 173 € / day or 6 € / to ice – BUCO Ice Pack

Savings: 151 € / day

for 300 days production: 45.300,-€ / year savings of electricity costs

The manufactured products that generate this are basically the falling film chiller (ice water 0.5 ° C) and the industrial ice maker (plate ice -0.5 ° C) to serve the products of industrial food refrigeration.

Ways of preserving fish quality

Fish preservation methods aim to deactivate tissue enzymes and eliminate the life of microorganisms. The methods can be categorized as follows:

Physical methods: These include cold, heat, ultraviolet and infrared rays, ultrasound, cooling, freezing, and drying.

Chemical methods: Chemical substances (preservatives) that are safe for humans are used to preserve fish, enhancing its taste, smell, color, and consistency. Examples include preservation with sodium chloride (NaCl), marinating with acetic acid salt or vinegar, smoking with phenols and acids, permitted antiseptics like benzoic acid and sodium benzoate, and antioxidants like ascorbic acid, sodium glutamate, and citric acid.

Biochemical methods: These methods utilize biologically active substances such as antibiotics, which have bacteriostatic and bactericidal effects. Fermentation processes involve the action of enzymes and microorganisms, resulting in specific flavors and aromas during the maturation of salted fish and production of preserves.

Cooling is an important technique to extend the shelf life of raw fish without significantly altering its properties and quality. The temperature is rapidly lowered close to the cryoscopic point, which is around -0.5ºC to -1.5ºC for freshwater fish and -0.8ºC to -2.2ºC for saltwater fish. Quick refrigeration immediately after fish capture is essential to preserve quality. The use of ice is a common method to achieve this, effectively lowering the temperature, minimizing biochemical and microbial effects, and extending the shelf life of fresh fish.

In this preservation process, fish are cooled based on the required storage time:

1.) For short periods, different forms of ice are used, depending on the size and shape of the fish.

Chip or plate ice: This modern method produces ice with a larger contact area, ranging from 1.5 to 6 mm in thickness and 2.5 to 5 cm2 in surface area. It does not damage the objects it comes into contact with.

2.) For longer periods:

In freezing preservation, low temperatures are applied to freeze the fish's tissue water and extend the storage time for considerably long periods (typically around 6 to 12 months) without substantial modification to the product's chemical structure. Freezing involves applying low temperatures such that the thermal center reaches minimum storage temperatures. The thermal center is the area that cools the slowest. In fish, it does not have a defined point due to dissolved solids, the nature of bound water, and the shape of the fish.

Freezing power is determined by the following effects:

- Elimination of liquid water by transforming it into ice, stopping all enzymatic activity.

- Thermal effect, cooling the treated products to temperature zones where biological activities are significantly reduced. The term "freezing" generally refers to the change of state from liquid to ice, while "ultra freezing" assures that the fish has been frozen "as quickly as possible" at temperatures below -18°C and stored below this temperature.

- Liquid ice is an emerging alternative for fish cooling. It is a suspension of an ice solution based on crystallized water, offering a greater cooling capacity compared to traditional methods. With a larger heat exchange surface, liquid ice exceeds the cooling capacity of traditional systems by 3 to 5 times. Despite being used for over twenty-five years, the first generation of liquid ice machines has not undergone significant changes.

Methodology

In order to comprehend the fish preservation process, it is necessary to consider the valuation of fish as a foodstuff, taking into account the following factors:

1. The chemical composition and the actual value of vitamins, proteins, and minerals, which ultimately characterize the nutritional level of the hydrobiological resource.

2. Quality parameters encompass taste, odor, structure, consistency, as well as the characteristics of the flesh (muscle), and the appearance in terms of shape, color, attractiveness, and overall presentation of the treated fish.

3. The freshness level, age of the fish after catching, and subsequent shelf life.

4. The suitability of the fish to be processed in a specific manner. Fish is highly perishable, therefore, it necessitates careful handling from the time of capture until serving or industrialization. The way in which the fish is handled during this period dictates the extent of alterations, which can be attributed to three causes:

- Enzymatic: Activities of endogenous enzymes.

- Oxidative: Aerobic degradation of fats.

- Bacterial: Action of internal and external microorganisms.

The speed at which these actions occur during fish decomposition relies primarily on the implementation of fundamental food preservation principles. Additionally, it is influenced by the fish species and fishing techniques employed. The greater the clarity and definition of these parameters, the higher the commercial value and quality of the hydrobiological resource.

Composition of fish flesh: When discussing the composition of a food, we can refer to the overall composition or the composition of specific parts, particularly the most commercially significant portions.

Regarding the proportion of flesh in the fish's total weight, it is important to clarify that flesh includes the muscles of the body, along with connective and fatty tissues, blood and lymphatic vessels, as well as some small or intramuscular bones. Flesh represents the primary edible portion of the fish, accounting for approximately half of its total weight on average.

Findings

Expanding knowledge on the use of the cold chain is crucial for obtaining high-quality fish raw material. This ensures both safety and organoleptic quality of fresh refrigerated fish, allowing for longer display time in display cases. Furthermore, it also applies to processed and frozen value-added fish. As part of the discussion, incorporating good processing practices within the processing, capture, and cultivation practices of aquaculture species or ocean seafood is vital for public health and the performance of the fish industry in the region. Academic entities should emphasize the use of the cold chain and provide specialized training by qualified professionals in industrial and semi-industrial cold systems available to small producers.

Conclusion

The cold chain is currently one of the most effective preservation technologies for ensuring excellent product quality in the storage and marketing of hydrobiological products over both short and long periods of time. All fish preservation methods aim to inactivate tissue enzymes and destroy living microorganisms. From the perspective of hydro-biological resources, these preservation methods can be categorized as physical, chemical, and biochemical. Cooling helps extend the shelf life of raw material without causing fundamental changes to its properties and quality. The optimal temperature for freshwater fish is between -0.5°C and -1.5°C, while for saltwater fish it is between -0.8°C and -2.2°C. For technological calculations, the cryoscopic point temperature of -1.0°C is commonly used. For short time periods, chip ice or plate ice can be used depending on the size and shape of the fish. For longer periods, freezing is employed, which involves applying low temperatures to freeze the water in fish tissues and increase storage time for extended periods.