General Manager

Sven-Olaf Klüe has been working in the field of design, manufacture and applications of pillow plate heat exchangers worldwide for 27 years. For the past 15 years, he has focused specifically on the process-related applications of pillow plate heat exchangers in industrial applications.

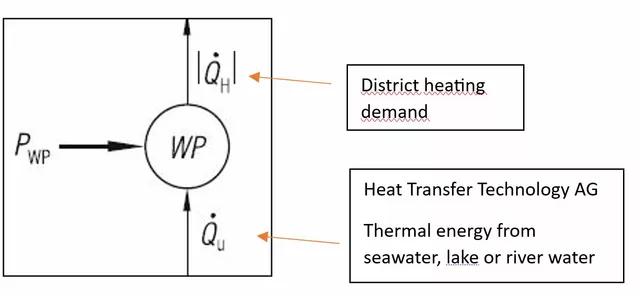

Alternative energy use (heat pump)

BUCO Falling Film Chiller in use as evaporator of a central heat pump system as project of existing heat recovery from the process

It is impossible to imagine a modern infrastructure without district heating grids. Currently, about 90% of district heating grids are operated with heat extraction from coal or gas-fired power plants, where the combustion of fossil fuels is the heat source.

In contrast, the use of seawater, lake or river water as a heat source in a heat pump process is more resource-efficient and sustainable. By operating the heat pump with regenerative electrical energy, considerable sustainable amounts of heat can be generated. Falling-film heat exchangers constructed from pillow plates can be used very successfully worldwide to operate heat pumps. The falling film heat exchanger serves as a very energy-efficient evaporator in which refrigerant is evaporated in various operating modes (flooded evaporation and dry expansion).

Our BUCO Falling Film Chiller support you in saving energy, e.g. in the basic supply of settlements. Rising energy costs are forcing municipalities to supply alternative forms of energy. Here, our BUCO Falling Film Chiller as heat exchanger offer an unbeatable alternative. Water is taken from nearby oceans, rivers or lakes as a heat reservoir by submersible pumps and passed over our BUCO Falling Film Chiller. Here, the BUCO Falling Film Chiller act as heat exchanger for the central heat pump system. The customers and process consultants appreciate the use of BUCO Falling Film Chiller because of the flexibility in heat transfer with different volume flows and temperatures, robustness (no destruction by icing), easy cleanability of an open system and a low control effort.

Application in heat pumps

The falling film heat exchanger as evaporator absorbs the heat flow Qu from the environment, for example by cooling large volume flows of seawater or brackish water, and thus evaporates the working fluid (green ammonia, CO2, R1234ze, etc.) of the heat pump. The use of the falling film as an evaporator in the heat pump circuit for district heating grids with the natural resource water offers the following basic advantages compared to other heat exchanger designs.

What type of renewable energy is right for me? Heat pumps as example of use

The basic supply of housing estates is achieved by means of heat and electrical energy through solar systems. For the cold season, the heat self-supply of the settlers is supplemented by a central offer, the local heat supply through a heat pump cascade. Water is taken from nearby rivers or lakes as a heat reservoir by means of submersible pumps and passed over our falling film chillers made entirely out of stainless steel.

Heat energy in buildings is consumed through central heating stations, typically situated in the basement of the building. The substation receives the heat energy and distributes it within the building based on the temperatures and controls designated in the substation. Within the central heating station, the building owner has the ability to set the internal temperatures of the rooms and other necessary parameters. The heat meter installed in the building quantifies the amount of heat energy consumed.

Most customers are connected to a remote reading system, which enables even more accurate measurement of heat energy consumption. A system with constant data connection allows for the swift detection of failures, losses, leaks, and full control of the heat energy network's operation. Most customers consistently invest in both technology and fuel exchange to reduce reliance on imported fossil fuels. On average, over two-thirds of heat production utilize biomass and waste heat. To fulfill peak demand, these customers also utilize natural gas, but have a comprehensive investment plan to achieve carbon neutrality and discontinue the use of fossil fuels as soon as practicable.

Heat pumps have the capability to replace fossil fuel heat generation, such as traditional boilers, up to a specific temperature threshold based on the type of refrigerant employed. A heat pump operates on a similar cycle as a refrigeration system, but at a higher temperature and pressure level. Leveraging its exceptional energy efficiency and utilization of waste heat sources, a heat pump is typically at least three times more sustainable than a conventional combustion boiler, even when powered by coal-fired electricity alone. Consequently, it only consumes one-third of primary energy. Apart from our extensive experience in refrigeration technology and ammonia as a refrigerant, Heat Transfer Technology AG has also been heavily engaged in heat pump applications for several years, and our heat pump portfolio stands among the most efficient on the market. We continuously strive towards its advancement.

Are heat transfer systems the right choice for you?

The lake or river water can drop to a temperature of 5°C in winter. The falling film chiller functions here as evaporators of the central heat pump system. The falling film chiller are designed in such a way that kW heat transfer is extracted from the lake or river water during evaporation. The water cools down to 1°C and is then returned to the river. The following aspects are decisive for the selection of these falling film chillers as evaporators for the central heat pump system:

- High heat transfer coefficient (k-value) due to the wavy structure of the pillow panel geometries.

- The evaporation temperature can be selected close to the outlet temperature of the water to minimise the exergy loss flow in the evaporator. In this way, high coefficients of performance of the heat pump can be achieved.

- Capacities of several MW per falling heat exchanger possible.

- The thermal energy in seawater can be used up to near freezing point without the risk of icing, so that the maximum thermal capacity can be extracted from the water.

- Temperature fluctuations between summer and winter operation are no problem.

- Usually, winter operation is the design point.

- Due to the open design, complete cleaning is possible without any problems, so that a fault-free and durable operation of the system can be guaranteed.

- Flexibility in the heat load capacity of the heat exchanger , both in terms of temperatures and the volumetric water flows

- High robustness of the systems (if extreme climatic conditions or conditions far from the design conditions that are far from the design, the units will not be destroyed, as they are not they will not be destroyed because they are open systems)

- Good cleanability of the open surfaces and distribution trough, even during water operation

- Low control effort of this heat pump

- Heat pump with low cost per kWh and minimal refrigerant used ideal for use of renewable energy

- Highly efficient with optimal heat transfer, low pressure drop of these heat pumps

- Easy access to the open systems of these heat pumps

- Easy to clean heat pumps ideal for use of renewable energy

- Cleaning during operation possible with these heat pumps

- Low tendency to fouling for this heat pump ideal for use of renewable energy

- No seals in this heat pump

- No destruction of the apparatus in case of ice formation of this heat pump

- Simplicity of control of these heat pumps

- Heat pumps completely made of stainless steel, also for salt water

- Special heat exchanger system design of these heat pumps possible

Conclusion

Environmentally sustainable district heating is accessible to customers in the required quantity and at the desired time. In a contemporary district heating system, customers can rest assured as homes are reliably supplied with heat and do not require any additional heating solutions. The district heating service provides high supply security and is safe to use. Additionally, district heating plays a vital role in reducing the carbon footprint of energy usage.

The heat energy recovered in the central heat pump system (heat recovery) is used to heat the primary circuit of the local heating supply to 12 - 15 °C in the flow. This primary circuit then supplies decentralised heat pump systems in the individual housing estates, which are used to produce both hot water (up to 45°C) by heating up and domestic hot water (60°C). Existing renewable energy is used to save the energy and costs that would otherwise have had to be spent in full.

Heat Transfer Technology AG many years of experience in the field of falling film heat exchangers and the implementation of the heat pump application near Kiel in Germany with the heat source Baltic Sea water, make us an excellent supplier for the delivery of the evaporator.